3D Printing

by 900lbs of Creative

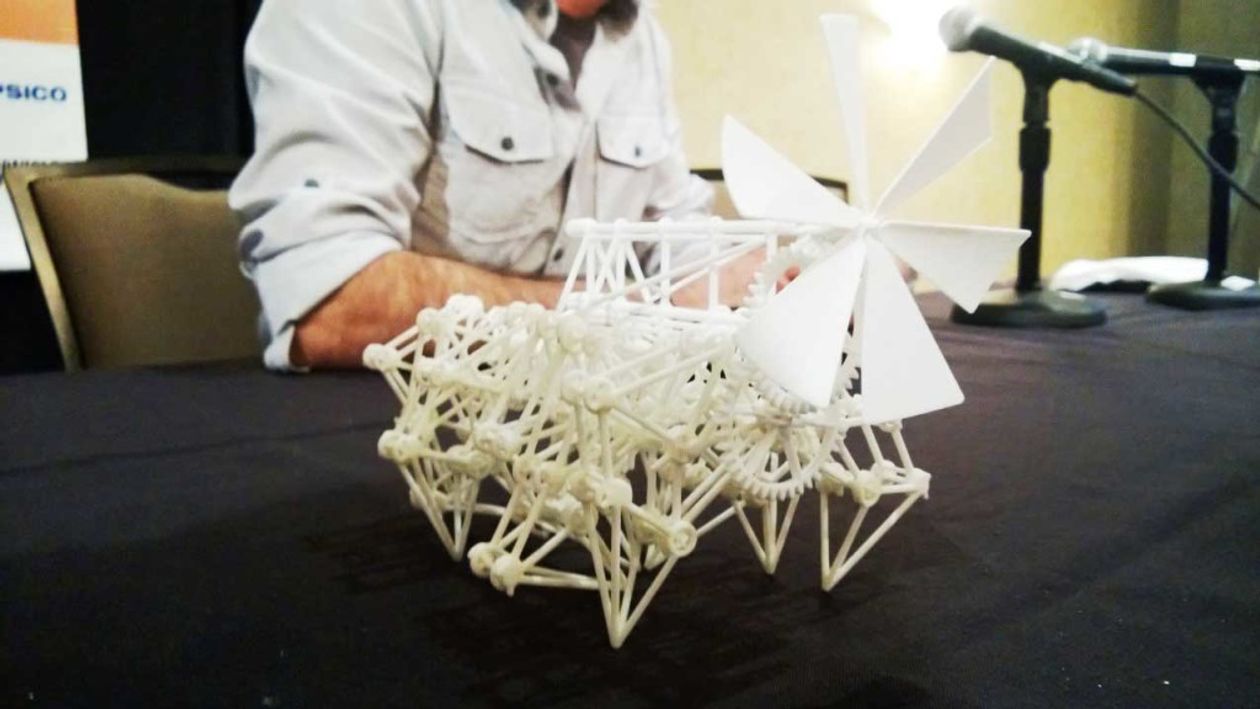

Of the many things we experienced at SXSW Interactive, the evolution of 3D printing was something that really stood out to us. 3D printing is quickly changing the manufacturing world. Since 3D printers can manipulate matter by moving atoms around to create real world materials, the possibilities are endless: Products will be available on demand, and the needs for large scale inventories will be gone. We are already seeing examples of this in use with Nike’s custom shoe soles and in Boeing’s new Dreamliner. Even consumer grade 3D printers are taking off with the Makerbot Replicator 2, the CubeX and Formlabs.

Arguably, the next stage of innovation for 3D printing will be how different materials can be incorporated into the process. While plastics are the dominant material of choice, woods and metals are becoming more widely adopted. Bioprinting is also expanding through companies like Organova, who are researching printing human analog cells, and Modern Meadow, who is looking into 3D printing edible meat.

While we aren’t looking to change the world with 3D printing, 900lbs looks to research how this important technology can revolutionize our pipeline and how that benefit can be passed down to our clients. It can aid us in educating clients and partners, giving them an ability to see beyond the limitations of the screen and physically interact with our services. In the end, this technology is rapidly changing; be sure to keep an eye on it, as its evolution should be an exciting one.